What are Inductors?

An inductor is a single or multiple loop(s) of wire featuring two terminals

An inductor is a single or multiple loop(s) of wire featuring two terminals

Inductors are used to store electrical energy generated by current passing through the loop(s) of wire. The electrical energy is stored in the form of magnetic energy. Inductors find application in industrial components such as transformers and motors.

Coupled inductors are used to create inductance-based transformers. Coupled inductors have a common magnetic path. Therefore, a variation in one inductor affects the other. These transformers can be used for power distribution or voltage conversion.

Choosing an inductor with a high operating frequency is beneficial when purchasing inductance-based transformers. A magnetic field is created when variations occur in the current passing through the inductor coil. So, a higher frequency denotes faster variations in passing current, which delivers a high-performing transformer.

Induction motors are extensively used in industrial settings. These motors work by converting the electrical energy in the inductors into mechanical energy. The magnetic force generated within the inductor coil is used for energy conversion.

A stater is the fixed component of an induction motor, which receives input current, and uses it to create a rotating magnetic field. This moving magnetic field comes into contact with another motor component – the rotor. The interaction generates current in the rotor, which in turn creates a magnetic field.

As the two magnetic fields (created by the stator and rotor) come into contact, torque is produced, which moves the rotor and accomplishes the task required of the motor.

This design of induction motors prevents the need for electrical contact between stator and rotor. This makes induction motors highly reliable for industrial settings. In addition, there are no components such as brushes in induction motors. This helps increase the life span of the motor.

Inductors can be classified into different types depending on the type of core they are wound around. The core is significant as it contributes to a stronger magnetic field. The magnetic force generated in an inductor with a solid core is greater than that created in an inductor that is simply a wound coil.

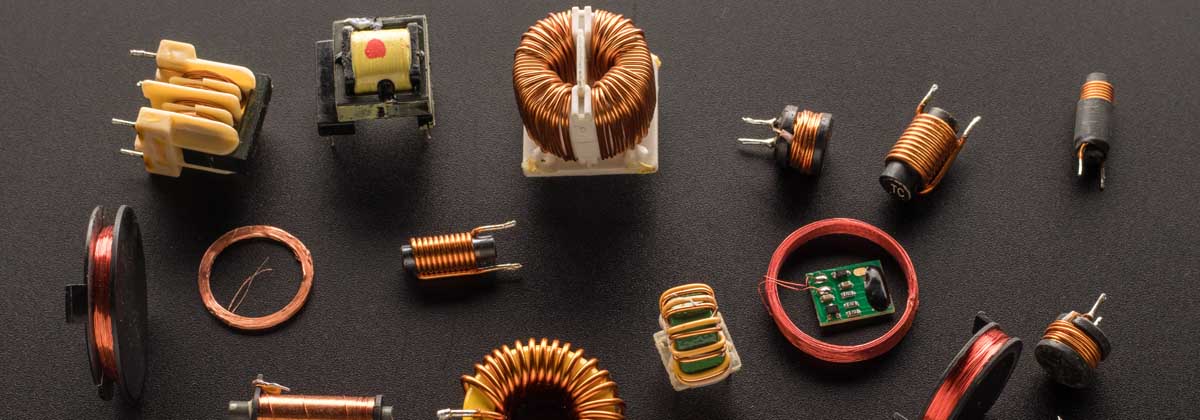

Some common types of inductors include:

Also referred to as air core inductors, ceramic core inductors are the most common and are used in applications that require high frequency input and a low inductance output.

The non-magnetic nature of ceramic ensures that the core does not contribute to any increase in permeability. Increase in permeability results in greater resistance to magnetic field formation, which affects inductor performance.

Another beneficial feature is ceramic’s minimal thermal co-efficient of expansion, which refers to the amount of expansion an object undergoes on heating. The low value of ceramic ensures that the inductor gives a steady output over a wide spectrum of operating temperatures.

Toroidal inductors have a core resembling a ring. The core is usually made of powdered iron or ferrite. These inductors are used in applications that require high inductance output at low frequencies. They are widely used in industrial controls, power supply equipment, power amplifiers, air conditioners, refrigerators and ballasts.

Iron powder or ferrite core may be used for power inductors. These inductors are common in applications where voltage conversion needs to occur. Power inductors stabilise current flow in circuits that have variable voltage or current.

AM Transformers Fulfils All your inductor Needs

AM Transformers bring to you a range of inductors for all your industrial needs. We deliver custom windings as well. Our inductors comply with safety standards recognised globally as well as in the UK. With over 20 years of experience in supplying wound components to businesses across UK, we have become a trusted name in the transformer industry.