They are compact, they are reliable and they are long lasting – so long as they are treated properly. The first printed circuit boards that most users would probably have seen had wires on them, with the components sticking through the printed circuit board and more often than not being connected underneath it via wires.

As technology has advanced over the years, the way they are constructed has changed many times. The technological leaps of the past decade have seen the complexity of the circuits that are able to be fitted on a printed circuit board increasing tremendously. Because they have no pins or other components that penetrate through the printed circuit board itself they can be designed to a much more compact spec which is one of the reasons they have become the preferred way to affix any type of an electronic component to a printed circuit board in recent years and now surface mounted components have become the norm.

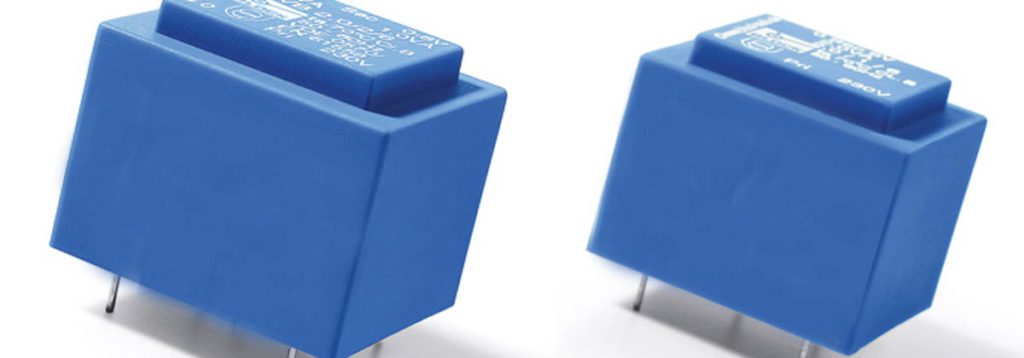

PCB mounted transformers are generally found somewhere above the surface of the circuit board, providing whatever voltage transformation or current transformation that may be required. They do not have sophisticated cooling mechanisms, so they tend to come with a rating for the maximum and minimum temperatures at which they should be run. So long as you keep between these ranges your printed circuit board PCB mounting transformer should last for many decades.

These PCB mounting transformers come in a variety of different capacities and sizes, ensuring that there are enough options for just about any imaginable product. Mounted PCB transformers tend to be inexpensive parts, which helps make printed circuit boards even more economically viable as a means to produce electronic components. Used in a variety of different applications, PCB transformers can step the voltage down to a safe level which makes them indispensable. Constructed on high quality double section metric bobbins designed to meet international standards, our PCB mounted transformers are fitted with modern pin terminals for a level of reliability you can trust.

With next day delivery and a bespoke service that offers our customers the ability to design to order for their specifications as well as those manufactured to designs and specifications that meet the insulation requirements visit us today for your PCB mounting transformer.